What is Digital HACCP Software and Why is It Important for Audit-Ready Compliance?

Digital HACCP software is a cloud-based platform that automates and digitizes Hazard Analysis and Critical Control Points (HACCP) protocols, replacing traditional paper-based food safety management systems. This technology ensures audit-ready compliance by maintaining real-time, tamper-proof records that meet regulatory requirements across global standards including FDA, EU, Codex, and GFSI.

The shift from manual documentation to digital solutions transforms food safety management through several key improvements:

- Automated monitoring of critical control points eliminates human error in temperature logging and safety checks

- Instant alerts notify teams of deviations before they escalate into compliance violations

- Centralized data storage provides immediate access to historical records during inspections

Audit readiness directly impacts both regulatory standing and market reputation. Food businesses face increasing scrutiny from health authorities, third-party auditors, and consumers demanding transparency. Digital HACCP software addresses this pressure by generating comprehensive audit trails automatically—documentation that would traditionally require hours of manual compilation becomes instantly available.

The technology creates a continuous compliance environment rather than a reactive scramble before scheduled audits. Teams can identify gaps proactively, implement corrective actions with documented evidence, and demonstrate systematic food safety practices. This preparedness reduces audit stress, minimizes non-conformance findings, and strengthens consumer confidence in brand integrity.

What Are the Key Features That Ensure Automated Compliance and Real-Time Monitoring in Digital HACCP Software?

Automated Compliance Features

Automated compliance features eliminate manual tracking gaps by sending instant alerts when critical control points (CCPs) deviate from established parameters. These systems trigger notifications to designated personnel the moment temperature thresholds are breached, cleaning schedules are missed, or monitoring intervals are overdue, enabling immediate corrective actions before minor issues escalate into food safety incidents.

Real-Time Monitoring Capabilities

Real-time monitoring capabilities transform how food businesses track CCPs throughout production cycles. Digital sensors continuously collect data on temperature, humidity, pH levels, and other critical parameters, feeding information directly into the HACCP platform. This constant surveillance detects anomalies within seconds rather than hours, dramatically reducing contamination risks that paper-based systems might miss between manual checks.

Advantages of Automation for Food Safety Protocols

Automation delivers three core advantages for food safety protocols:

- Accuracy: Eliminates human error in data recording and calculation, ensuring precise documentation of every measurement

- Consistency: Standardizes monitoring procedures across all shifts, locations, and team members without variation

- Efficiency: Reduces time spent on manual documentation by 60-70%, allowing staff to focus on proactive safety measures

The software automatically logs every reading, creates time-stamped records, and flags deviations requiring corrective actions. When a CCP falls outside acceptable limits, the system immediately documents the event, prompts staff to implement predefined corrective measures, and tracks resolution steps—creating a complete audit trail without additional paperwork.

How Audit-Ready Reporting and Traceability Make Audits Easier with Digital HACCP Software

Instant Documentation for Auditors

Audit-ready reporting transforms the inspection process by generating instant, comprehensive documentation that auditors can review immediately. Digital HACCP software creates complete audit trails that timestamp every action, from temperature checks to corrective measures, eliminating the scramble to locate scattered paperwork hours before an inspection.

Customizable Reports for Regulatory Compliance

Customizable reports adapt to specific regulatory frameworks, whether you’re preparing for a USDA visit or a third-party certification. The software formats data according to auditor preferences—daily temperature logs, CCP monitoring summaries, or deviation reports—all accessible within seconds through filtered searches or pre-configured templates.

Built-in Compliance with Regulatory Standards

Built-in compliance with Codex, EU, FDA, and GFSI standards means the system automatically structures documentation according to regulatory expectations. When an auditor requests proof of metal detector calibration or allergen control verification, the platform pulls exact records matching their requirements without manual reformatting.

Verifiable Evidence with Tamper-Proof Records

Tamper-proof electronic records provide verifiable evidence through digital signatures, edit histories, and locked entries. Unlike paper logs where dates can be altered or pages removed, blockchain-secured or encrypted records show:

- Original entry timestamps

- User identification for each action

- Modification history (if corrections were made)

- Supervisor approval chains

This use of blockchain technology not only enhances security but also significantly improves transparency in audit processes as highlighted in this article on the impact of blockchain-based audit trails.

Quick Traceability for Recalls and Investigations

Traceability extends beyond internal operations to ingredient sourcing, linking supplier certifications, lot numbers, and delivery records directly to finished products. During recalls or contamination investigations, this connected data reveals the complete journey from raw material to consumer in minutes rather than days.

Why Is Cloud-Based Storage Crucial for Accessibility, Collaboration, and Data Security in Digital HACCP Software?

Cloud storage transforms how food safety teams protect and access their compliance data. Automated backup mechanisms eliminate the risk of losing critical HACCP records due to hardware failures, natural disasters, or human error. Version control capabilities track every modification to food safety plans, allowing teams to review historical changes and restore previous versions when needed—a feature particularly valuable during audits when inspectors question documentation updates.

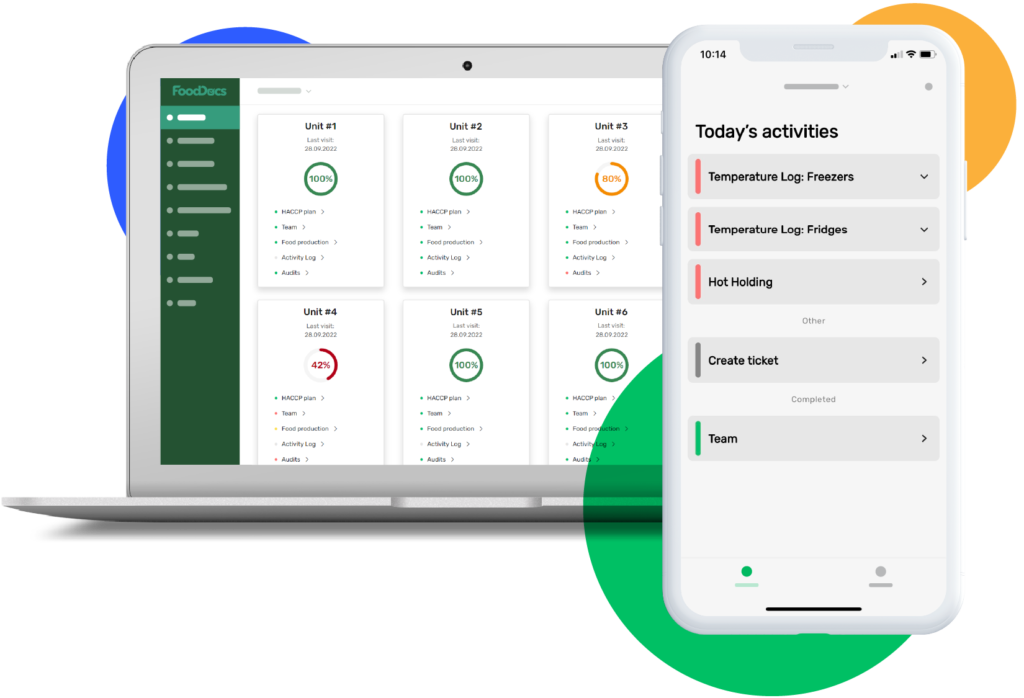

Multi-site collaboration becomes effortless when all team members access the same centralized database. A quality manager in one facility can instantly review temperature logs from another location, while corporate teams monitor compliance across their entire operation from a single dashboard. This centralized approach to data backup ensures consistency in food safety protocols regardless of geographic boundaries.

Mobile access revolutionizes daily operations by enabling real-time data entry during floor inspections. Food safety professionals can:

- Record temperature readings directly at refrigeration units

- Document corrective actions immediately when deviations occur

- Upload photographic evidence of sanitation procedures

- Complete checklists while walking production lines

The flexibility of cloud-based systems means inspectors no longer need to return to desktop computers for data entry, reducing delays between observation and documentation. This immediate recording capability strengthens the accuracy of compliance records while supporting faster response times to potential food safety issues.

How Do Customizable Workflows, Templates, and Integration Capabilities Cater to Diverse Business Needs with Digital HACCP Software?

Customizable workflows adapt to each business’s unique operational structure rather than forcing companies into rigid, one-size-fits-all processes. Digital HACCP platforms allow food safety managers to configure task sequences, monitoring parameters, and documentation formats that match their specific production lines, whether running a small bakery or a multi-facility meat processing operation. This flexibility extends to industry-specific checklists that reflect the distinct hazards and control points relevant to different food sectors—dairy operations require different monitoring protocols than seafood processing facilities.

The ability to define corrective action procedures within the software creates alignment between internal processes and regulatory expectations. Businesses can establish custom response protocols for temperature deviations, contamination events, or equipment failures that reflect their operational capabilities and compliance requirements. SOPs customization ensures that documented procedures match actual workplace practices, increasing staff compliance and reducing confusion during critical incidents.

Integration capabilities transform isolated HACCP systems into connected compliance ecosystems. When HACCP software connects with ERP systems, quality management platforms, or production scheduling tools, data flows automatically between systems without manual re-entry. A temperature reading captured at a CCP instantly updates inventory systems, triggers production holds if needed, and generates compliance documentation—all without human intervention. This interconnected approach eliminates transcription errors while providing real-time visibility across the entire food safety management framework.

How Do Advanced Technologies Like AI-Powered Features Change Hazard Analysis Automation with Digital HACCP Software?

AI-powered features are revolutionizing hazard analysis by transforming it from a manual, time-consuming process into an intelligent, automated system that identifies risks quickly and accurately. Machine learning algorithms analyze large amounts of data from production environments, past incidents, and regulatory databases to automatically flag potential biological, chemical, and physical hazards specific to each operation.

These smart systems are exceptional at automating hazard analysis by learning from patterns in thousands of food safety situations. The software can predict contamination risks based on factors like ingredient combinations, processing temperatures, equipment age, and seasonal changes. When a new product starts being made, AI creates detailed HACCP plans in minutes—a job that usually took hours of expert analysis.

Predictive Analytics for Risk Assessment

The software’s ability to predict using analytics allows it to evaluate how serious a risk is and how likely it is with accuracy based on data. The system looks at each identified hazard and compares it to regulatory limits, industry standards, and parameters specific to the facility in order to determine which critical control points are most important. This automatic risk assessment gets rid of personal interpretation while making sure food safety principles are applied consistently.

Continuous Compliance Monitoring

AI-driven gap analysis constantly compares current practices with changing regulatory standards, automatically pointing out compliance deficiencies before audits happen. The technology adjusts recommendations as regulations change, keeping HACCP plans up to date without manual effort. Some platforms even suggest optimized monitoring frequencies and control measures based on real-time operational data, creating flexible food safety protocols that respond to actual facility conditions instead of fixed assumptions.

Interestingly, the impact of AI-powered features isn’t just limited to the food industry. For instance, AI-powered Safety Management Systems (SMS) are revolutionizing aviation safety as well. Just like in the food sector where AI automates hazard analysis, similar advancements are being made in aviation with AI automating risk assessments and enhancing safety protocols.

Why Are User-Friendly Interfaces with Mobile Support Essential for On-the-Go Inspections Using Digital HACCP Software?

Can inspectors effectively conduct real-time compliance checks without mobile accessibility? No—a user-friendly interface with mobile support transforms how food safety teams perform inspections across multiple locations. Intuitive mobile applications allow inspectors to complete temperature checks, document observations, and record corrective actions directly from the production floor without returning to desktop systems.

Mobile-enabled digital HACCP software eliminates the lag between observation and documentation. Inspectors capture photos of equipment conditions, scan barcodes for lot tracking, and receive instant deviation alerts when critical control points fall outside acceptable ranges. This immediate data entry prevents memory-related errors that plague paper-based systems.

Key capabilities that define effective mobile support include:

- Touch-optimized interfaces requiring minimal training

- Offline functionality for areas with limited connectivity

- Bluetooth integration with temperature probes and IoT sensors

- Voice-to-text features for hands-free documentation

- Digital signature capture for verification workflows

The design simplicity matters significantly for adoption rates. Complex navigation structures create resistance among frontline staff, while streamlined interfaces encourage consistent usage. Mobile applications with clear visual cues, logical menu structures, and minimal data entry requirements ensure inspectors spend more time monitoring food safety and less time struggling with technology.

Cloud synchronization means management teams access inspection results instantly, enabling rapid response to identified hazards across distributed operations.

How Supplier Management Functionality Enhances Supply Chain Traceability Within Digital HACCP Software Solutions

Supplier management features centralize vendor documentation, certificates, and compliance records within a single platform, eliminating scattered spreadsheets and filing cabinets. This consolidation enables food businesses to instantly verify supplier credentials during audits and trace ingredient origins throughout the supply chain.

Digital HACCP platforms track each ingredient from its source through every production stage using lot tracking systems that assign unique identifiers to batches. When contamination issues arise, teams can pinpoint affected products within minutes rather than days, enabling targeted recalls that minimize waste and protect brand reputation.

Advanced solutions incorporate blockchain technology to create immutable records of ingredient journeys. Each transaction—from farm to processing facility to distribution center—receives a timestamped, tamper-proof entry that auditors can verify independently. This transparency satisfies increasingly stringent regulatory requirements while building consumer confidence.

The software automates supplier approval workflows by flagging expiring certifications, triggering renewal reminders, and blocking orders from non-compliant vendors. Quality teams receive alerts when supplier audit scores drop below acceptable thresholds, prompting immediate corrective action discussions.

Integration with procurement systems automatically populates supplier data into HACCP records, linking purchase orders to specific production runs. This connection transforms raw ingredient deliveries into fully documented components of finished products, creating comprehensive traceability maps that demonstrate complete supply chain visibility during regulatory inspections.

How Does Digital HACCP Software Save Costs and Ensure Compliance?

Digital HACCP software helps businesses save money by replacing paper-based systems that require a lot of time and resources. With this software, companies can expect to reduce their reliance on paperwork by up to 70%, resulting in significant savings on printing, filing, and administrative costs.

Here are some ways digital HACCP software achieves cost savings:

- Reduced labor costs: The software automates tasks such as monitoring, sending alerts, and generating reports, which reduces the need for manual work and lowers labor expenses.

- Lower audit preparation expenses: With digital HACCP software, businesses can easily access organized and compliant records whenever an audit is conducted. This eliminates the need for extensive preparation and reduces costs associated with audit processes.

- Decreased risk of fines: By ensuring regulatory compliance through automated monitoring and documentation, the software helps businesses avoid fines that may result from non-compliance or failed inspections.

- Minimized product waste: The software’s ability to detect temperature deviations and contamination risks early on prevents product spoilage or waste, leading to cost savings in terms of discarded inventory.

In addition to these financial benefits, digital HACCP software also offers operational advantages that contribute to overall cost efficiency.

Here are some operational benefits of using digital HACCP software:

- Centralized platform: The cloud-based nature of the software eliminates expenses associated with physical document storage and retrieval systems. All records are stored securely online, reducing costs related to maintaining physical storage facilities.

- Training time reduction: When new employees join the organization, they need to be trained on how to perform their tasks effectively. With standardized digital workflows provided by the software, training becomes easier and faster compared to teaching employees fragmented paper processes.

- Real-time visibility: The software provides real-time insights into food safety operations, allowing businesses to identify inefficiencies or bottlenecks in their processes. By addressing these issues promptly, resources can be allocated more efficiently and costs can be minimized.

Overall, digital HACCP software not only helps businesses save money directly through reduced expenses but also improves operational efficiency which indirectly leads to cost savings.

Learn more Food Safety Training Software: The Smarter Way to Train, Track and Certify Staff